|

|

|

Alerion Yachts commissioned Luther's Welding & Fabrications to build the rudder skeleton for their yacht model Express 20 club racer. The yacht’s rudder had to be rugged enough to handling high speeds in a tough marine environment; this required a rudder skeleton that is rigid and precise.

To meet these criteria, our design engineers first modeled the assembly using SolidWorks. Marine environments are a harsh atmosphere for metals, and therefore the material choice was stainless steel type 316 because of its superior overall resistance to corrosion and pitting. It also has excellent welding and forming characteristics.

Manufacturing began with preparing the assembly cut list using various machining processes, ...

|

|

|

|

|

|

|

Guiding a 28' day sailing yacht with a 5700 lb. displacement requires a strong, precise rudder. That's why Alerion Yachts trusted Luther's Welding & Fabrications to construct the rudder skeleton for their Model AE 28 rudder shaft.

This project is a great example of our diverse manufacturing capabilities in the marine industry. To set up the 4 skeletons required for the order, design and assembly drawings were first completed in SolidWorks. The material required was type T304 stainless steel tubes that were 2.25" x .25" and (3x) .5" x .065", with an overall part length of 38".

Manufacturing began with preparing the tubes using various machining processes including a band saw to cut the tubes to size (15.75", ...

|

|

|

|

|

|

|

A customer in Portsmouth, RI gave us the task of fabricating an aluminum fuel tank for the yachting industry. This tank is just one example of why, for over 20 years, Luther's Welding & Fabrications has been an industry leader in fabrication of marine fuel tanks.

This 125 gallon diesel fuel tank is used for a US Coast Guard 7.9 meter FRC Cutter. It was constructed of 1/4" thick 5086 aluminum for its high strength, puncture resistance, and corrosion fighting oxide layer, all of which make it an excellent match for yachting.

Through SolidWorks for CAD design, our experienced engineers designed a tank that was 48.82" in length, 37.40" in width and 18.66" in height. To form the many complex components that make up the ...

|

|

|

|

|

|

|

Luther's Welding & Fabrications specializes in manufacturing custom built assemblies and products for the marine Industry, and we have led the way in production of fuel tanks for the yachting industry since 1971.

This 26 gallon Bridge Deck diesel fuel tank was constructed of 3/16" thick type 5052 aluminum. This material is a great option for a marine atmosphere because of its good workability, high fatigue strength, medium static strength, and excellent resistance to corrosion, especially from salt water.

Starting with SolidWorks for CAD design, our engineers designed a tank that was 51.50" in length and 13.75" in height. To form the many intricate components that make up the tank, our highly skilled operators ...

|

|

|

|

|

|

|

Although Luther's Welding & Fabrications specializes in the marine industry, but we also produce custom metal fabrication products for customers in many other industries. One example of a non-marine application is this custom bases plate assembly for an architectural art display.

This 21.75” high bases plate assembly needed to be constructed of stainless steel type 304L because of its ability to retain its appearance, which is necessary for an outdoor art display. It also excels in its durability against a wide range of environmental elements and corrosive media, especially the kind these art displays will be exposed to in the Bristol, Rhode Island winters and summers.

Our engineering team reviewed the 2D CAD drawings ...

|

|

|

|

|

|

|

A company in Woonsocket, RI contacted Luther's Welding & Fabrications to manufacture two centrifugal pump impellers for a medical waste application. The impeller had to be precisely designed and fabricated to ensure superior wear resistance and consistent performance over time.

For this project, we designed the impeller using SolidWorks. The material was hot rolled steel, chosen for its ability to provide good resistance to abrasion and therefore a longer blade life, which is very important to a pump that is removing solid medical waste. The overall dimensions of the impeller were 32.876" in diameter, 11" height (without blades), and would be equipped with 5" hubs.

Several of our cutting-edge, large capacity ...

|

|

|

|

|

|

|

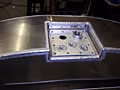

The project highlighted here was designed and fabricated for a manufacturer of swimming pools. Our background providing products for the harsh environments of the marine industry put us in good stead to accommodate the rigors of chlorination and exposure to the elements that this product would see. From the customer supplied specifications we developed a CAD design in SolidWorks. Final dimensions were 3" in length and width, and 3.5" in height, with (4x) 0.44" diameter holes. The tabs are composed of a hot rolled angle steel, this preformed shape made additional forming unnecessary, driving down the overall cost of the item. The angle steel was cut on our band saw, and then moved onto one of our CNC machining centers. Once all of the ...

|

|

|

|

|

|

|

Luther's Welding & Fabrications was commissioned by Swimex, a therapeutic pool manufacturer, to take on the complete fabrication of this Floor Lock Assembly. The assembly would be designed to produce 100 custom locking tabs with overall dimensions of 5.37" x 1.5".

This project would utilize all of our diverse engineering and manufacturing capabilities. Fabrication included highly engineered tooling and work holding fixtures, all specially developed for this floor lock assembly.

Once the design was modeled in SolidWorks and approved, we began the manufacturing process. Fabrication was completed primarily with our extensive CNC machining capabilities, which included CNC plasma cutting, drilling, band saw, and ABS ...

|

|

|